We can provide power transformer which use for 117V, 220V, 230V, 240V.

YouTube channel > Otomon YouTube Channel

Facebook Channel: Otomon Vintage FB

YouTube channel > Otomon YouTube Channel

Facebook Channel: Otomon Vintage FB

I will give discount 10% or more for all item in my eBay listing, Contact Us for more detail

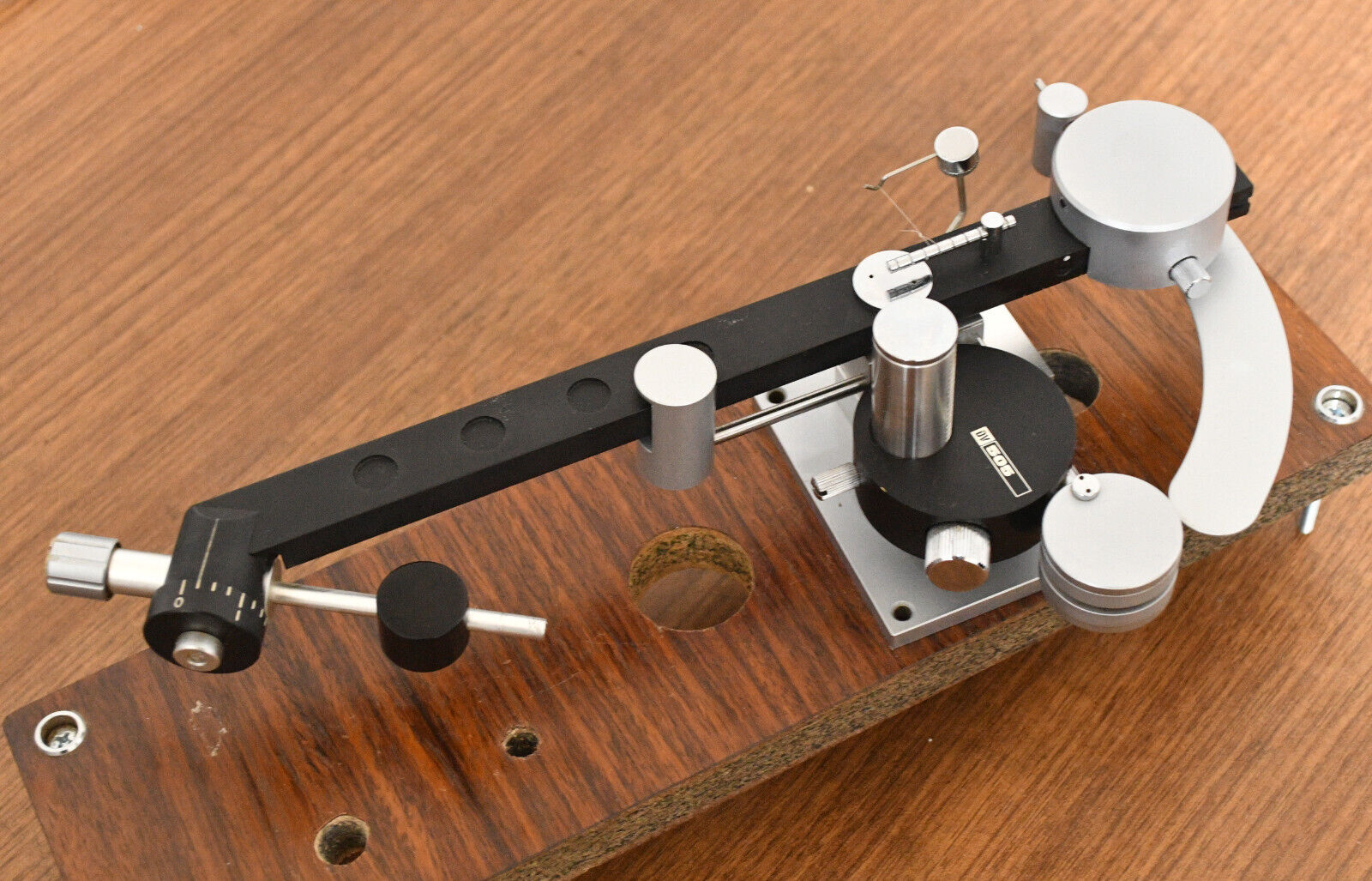

Extra RARE * NOS * SATIN AR-1 TWO BALLS THREE POINTS SUPPORT tonearm

Extra RARE * NOS * SATIN AR-1 TWO BALLS THREE POINTS SUPPORT tonearm.

This is one of the hardest to be found audio item in Japan, TWO BALLS THREE POINTS SUPPORT tonearm manufactured by SATIN, model AR-1.

This is new old stock item, never used before.

Specification:

Do you know what the sound of a record would be like if the cartridge did not move up and down or horizontally at all?

The stereo tonearm must be as solid and as immovable as a desk cutter race that costs tens of millions of yen. Even if the needle tip of the cartridge does not move, if the head shell moves, an output will be generated just as if the needle tip had moved.

The Satin stereo tonearm is completely fixed on both the horizontal and vertical rotation axes during normal recording, and is an arm that does not move acoustically at all. Furthermore, the vertical tracking angle of the cartridge can be matched to the vertical cutting angle of the record with an accuracy of 0.01°. At this point, you will realize that even records that were previously thought to have poor sound quality are not bad records, and that there is not a single record with poor sound quality.

The tonearm is not selected based on its tracing ability, but rather it is something that the arm must naturally have, and we have entered an era in which we must choose a cartridge based on how little it acoustically moves and whether it can be perfectly matched to the vertical cutting angle.

If the vertical cutting angle of the record and the vertical tracing angle of the cartridge do not match, resulting in a difference of α°, and if the vertical amplitude of the record is a mm and the speed at which the stylus traces the record is V mm/sec, then the time of the acoustic wave a(t) will advance or delay by atan α/Vsec as the amplitude a changes. Since a(t) contains an infinite number of frequency components, extremely complex frequency modulation occurs between all of them, generating an infinite number of frequency components that were not included in the original a(t), completely changing the sound quality of the record. Therefore, unless α = 0°, the record cannot be played correctly. Humans can easily tell that sound quality changes even when α = 0.01°.

Why does the tone arm vibrate?

There are four main causes of vibration:

1. Eccentricity and warping of the record, which mainly has frequency components much lower than the sound heard by the ear.

2. The grooves in the record snake up, down, left, right, and right due to the music.

3. When there is even the slightest amount of wobble anywhere on the tone arm, especially on the horizontal and vertical rotation axes.

4. When the structural parts that make up the tone arm are vibrating freely and making noise.

This is one of the hardest to be found audio item in Japan, TWO BALLS THREE POINTS SUPPORT tonearm manufactured by SATIN, model AR-1.

This is new old stock item, never used before.

Specification:

Do you know what the sound of a record would be like if the cartridge did not move up and down or horizontally at all?

The stereo tonearm must be as solid and as immovable as a desk cutter race that costs tens of millions of yen. Even if the needle tip of the cartridge does not move, if the head shell moves, an output will be generated just as if the needle tip had moved.

The Satin stereo tonearm is completely fixed on both the horizontal and vertical rotation axes during normal recording, and is an arm that does not move acoustically at all. Furthermore, the vertical tracking angle of the cartridge can be matched to the vertical cutting angle of the record with an accuracy of 0.01°. At this point, you will realize that even records that were previously thought to have poor sound quality are not bad records, and that there is not a single record with poor sound quality.

The tonearm is not selected based on its tracing ability, but rather it is something that the arm must naturally have, and we have entered an era in which we must choose a cartridge based on how little it acoustically moves and whether it can be perfectly matched to the vertical cutting angle.

If the vertical cutting angle of the record and the vertical tracing angle of the cartridge do not match, resulting in a difference of α°, and if the vertical amplitude of the record is a mm and the speed at which the stylus traces the record is V mm/sec, then the time of the acoustic wave a(t) will advance or delay by atan α/Vsec as the amplitude a changes. Since a(t) contains an infinite number of frequency components, extremely complex frequency modulation occurs between all of them, generating an infinite number of frequency components that were not included in the original a(t), completely changing the sound quality of the record. Therefore, unless α = 0°, the record cannot be played correctly. Humans can easily tell that sound quality changes even when α = 0.01°.

Why does the tone arm vibrate?

There are four main causes of vibration:

1. Eccentricity and warping of the record, which mainly has frequency components much lower than the sound heard by the ear.

2. The grooves in the record snake up, down, left, right, and right due to the music.

3. When there is even the slightest amount of wobble anywhere on the tone arm, especially on the horizontal and vertical rotation axes.

4. When the structural parts that make up the tone arm are vibrating freely and making noise.

Regarding 1, I don't think there's any need to explain this.

Regarding 2, this should be considered in two parts. One is that the needle tip receives an acoustic vibrational force as a reaction from the groove due to the mechanical impedance of the cartridge, and this does not include any components other than the frequency components of the original sound recorded. This is the same force that is received when a tiny piece of the silent groove of a record is attached to a machine called a vibrometer, and the needle tip is vibrated up and down and left and right by this, instead of a record.

However, the other is that when the needle tip is vibrated up and down and left and right by the record, it is completely different, the needle tip and the record groove are constantly sliding relative to each other, and when the sound groove is modulated, the inclination of the groove surface that the needle tip touches will necessarily change from when it is a silent groove.

The direction perpendicular to the groove surface at the two points where the needle tip touches the record is called the normal line, and the direction of this normal line changes from moment to moment due to acoustic waves.

The stylus receives these two normal forces from the groove, and the sum of their vertical components is exactly equal to the stylus pressure. The vertical component is always constant, but if the normal is constantly changing, the horizontal component will constantly change, and the total force in the normal direction will change from moment to moment along with the acoustic wave. The tangential direction in which the groove surface perpendicular to the normal and the stylus slide relative to each other also changes from moment to moment, and the total pressure in the normal direction also changes, and since the frictional force is proportional to the total normal pressure, the sliding frictional force also changes from moment to moment. To make matters worse, the frequency components of the force in this case include ones that are completely different from the frequency components of the original acoustic wave. The vertical and horizontal changes in the magnitude of this total normal pressure and frictional force are about 10% to 20% of the cartridge's stylus pressure. However, the change in the forward and backward components of the total normal pressure can be almost equal to the stylus pressure. As the cantilever changes greatly in the forward and backward directions, the AR-1M and AR-1S have a device that adjusts the height of the vertical movement fulcrum of the arm to an accuracy of 5μ in order to make the arm's rotational efficiency zero, and to accurately align the vertical movement fulcrum of the arm with the stylus tip, i.e., the record surface. A sphere sandwiched between two 90° cones from above and below comes into contact with each other on a circular line. If the radius of the sphere is R, then the radius of the circle is R/√2. When R = 0.75mm, it becomes R/√2 = 0.5033mm. The total weight of the moving parts of the AR-1 is about 280g, the coefficient of static friction between the cone and the steel ball is 0.115, and the normal direction is 45°, so the pressure in the total normal direction is 280g x √2 ≒ 396g, and a static friction force of 396g x 0.115 = 45.6g acts on a circular line. Therefore, to rotate the arm horizontally, a rotational efficiency of 45.6g x 0.5033mm = 22.95mmg is required. However, the effective horizontal rotation length of the AR-1 cantilever is 250.5mm x cos21.5° = 233mm, so unless a force of 22.95mmg ÷ 233mm = 0.0985g or more is applied perpendicular to the cantilever at the tip of the needle, the arm will not start rotating.

Below that force, the cone and the sphere are considered to be completely fixed together. Therefore, the shell of the arm does not shake at all.

In reality, the static friction force of the steel ball on the other side is 0.0158g, and the arm will not move unless a total force of 0.1143g or more is applied. The same calculation can be done for vertical movement, and the value is 0.132g.

The braking force of the AR-1 series due to static upward friction is fundamentally different from that of oil dampers and electromagnetic braking, where the braking force is only generated by the arm moving, that is, by the arm swinging, and the arm does not swing at all when the external force acting on the stylus tip is below a certain value.

Unlike other general arms, the AR-1 series does not vibrate wildly, so you can enjoy a very stable and reassuring playback with no shaking of the sound image.

About 3: How was the horizontal and vertical rotation mechanism with absolutely no wobbling realized? For two objects to rotate lightly while touching each other, a gap is necessary. This is because the precision of machining cannot be infinitely reduced. Even ultra-precise ball bearings have a 0.005mm (5μ) looseness, or gap. Normally, two ball bearings are used on each of the horizontal and vertical rotation axes of a tone arm. These two ball bearings should be spaced as far apart as possible, but tone arms are rarely spaced more than 50mm apart. Since there is a 0.005mm gap for one bearing, there may be a 0.01mm gap for two bearings. In other words, there is a 0.01mm wobble at 50mm. However, the distance between the rotation axis and the tip of the pickup needle is usually about 250mm, so the wobble is magnified five times at the needle tip, resulting in a 0.05mm wobble. This corresponds to the maximum amplitude of 50μm recorded on a record. From this, I think you understand that a general ball bearing should not be used for a tone arm.

So, what about a single-point support? As shown in the diagram, the center of rotation changes with the rotation, and the most crucial defect is that the axis of the vertical movement is not fixed at all. Stereo vibration is a vibration in a plane perpendicular to the sound groove, but rotational movement in that plane is completely unnecessary and harmful, and the vertical rotation axis of the tone arm must be fixed exactly perpendicular to the direction of the sound groove, that is, the horizontal projection direction of the cartridge cantilever. If the axis is rotated even slightly away from this perpendicular angle, the cartridge will inevitably rotate. From this, I think you understand that a general single-point support mechanism should not be used for a tone arm.

Knife edges do not have the defect of the direction of the vertical rotation axis being indefinite, but the problem of the center of rotation moving slightly when moving up and down remains. And for horizontal rotation, it is unavoidable to use ball bearings.

So, I was completely at a loss as to what to do, and because of this difficult problem, I was unable to manufacture a tone arm from Satin.

This seemingly unsolvable problem is actually very simple once you solve it, so if you look at the explanatory diagram, I think you will immediately understand.

A ball sandwiched between two conical surfaces makes circular contact with each conical surface. Therefore, the center of rotation does not move at all.

There is another ball on the side, which rolls on the disk.

The line connecting the centers of these two balls is fixed as the axis of up and down rotation, so it is necessary to make this exactly perpendicular to the axis of the cartridge.

The contact is only due to the weight of the tone arm, so there is absolutely no gap between them.

It is supported by only three points, the two balls and the cartridge stylus, so in principle there is no wobble at all. In addition, the vertical and horizontal axis rotation mechanism developed by Satin simultaneously provides the necessary damping action for a tone arm and the ability to completely cancel the inside force that changes from moment to moment due to modulation of the sound groove.

Regarding 4, in order to reduce the Q of a metal material to a non-vibrational level, a damping material of at least the same weight as the metal material is required. Since the specific gravity of the damping material is usually close to 1, a damping material of at least several times the volume of the metal material is required. There are some methods that harden the front and back of the pipe with anodized aluminum of only a few tens of microns in thickness, while the inside remains the original metal, or that increase loss by creating countless cracks on the surface of the pipe, or that attach a rubber-like damping material 1 to 2 mm thick to only one side of the metal surface, but all of these only have a moderate effect. Even if the layer of damping material is somewhat thin, it is necessary to make a true sandwich structure in which it is tightly sandwiched between structural materials that maintain rigidity.

The headshell of the Satin AR-1 series has a complete sandwich structure in this sense, and the arm pipe of the AR-1M and AR-1S also has a complete sandwich structure.

Furthermore, the same one as the IC-16 (see separate catalog) is built into all of the AR-1 series.

This item was SOLD OUT, you can ask me for ordering the same one or contact to me to get notification of the same one.

Regarding 2, this should be considered in two parts. One is that the needle tip receives an acoustic vibrational force as a reaction from the groove due to the mechanical impedance of the cartridge, and this does not include any components other than the frequency components of the original sound recorded. This is the same force that is received when a tiny piece of the silent groove of a record is attached to a machine called a vibrometer, and the needle tip is vibrated up and down and left and right by this, instead of a record.

However, the other is that when the needle tip is vibrated up and down and left and right by the record, it is completely different, the needle tip and the record groove are constantly sliding relative to each other, and when the sound groove is modulated, the inclination of the groove surface that the needle tip touches will necessarily change from when it is a silent groove.

The direction perpendicular to the groove surface at the two points where the needle tip touches the record is called the normal line, and the direction of this normal line changes from moment to moment due to acoustic waves.

The stylus receives these two normal forces from the groove, and the sum of their vertical components is exactly equal to the stylus pressure. The vertical component is always constant, but if the normal is constantly changing, the horizontal component will constantly change, and the total force in the normal direction will change from moment to moment along with the acoustic wave. The tangential direction in which the groove surface perpendicular to the normal and the stylus slide relative to each other also changes from moment to moment, and the total pressure in the normal direction also changes, and since the frictional force is proportional to the total normal pressure, the sliding frictional force also changes from moment to moment. To make matters worse, the frequency components of the force in this case include ones that are completely different from the frequency components of the original acoustic wave. The vertical and horizontal changes in the magnitude of this total normal pressure and frictional force are about 10% to 20% of the cartridge's stylus pressure. However, the change in the forward and backward components of the total normal pressure can be almost equal to the stylus pressure. As the cantilever changes greatly in the forward and backward directions, the AR-1M and AR-1S have a device that adjusts the height of the vertical movement fulcrum of the arm to an accuracy of 5μ in order to make the arm's rotational efficiency zero, and to accurately align the vertical movement fulcrum of the arm with the stylus tip, i.e., the record surface. A sphere sandwiched between two 90° cones from above and below comes into contact with each other on a circular line. If the radius of the sphere is R, then the radius of the circle is R/√2. When R = 0.75mm, it becomes R/√2 = 0.5033mm. The total weight of the moving parts of the AR-1 is about 280g, the coefficient of static friction between the cone and the steel ball is 0.115, and the normal direction is 45°, so the pressure in the total normal direction is 280g x √2 ≒ 396g, and a static friction force of 396g x 0.115 = 45.6g acts on a circular line. Therefore, to rotate the arm horizontally, a rotational efficiency of 45.6g x 0.5033mm = 22.95mmg is required. However, the effective horizontal rotation length of the AR-1 cantilever is 250.5mm x cos21.5° = 233mm, so unless a force of 22.95mmg ÷ 233mm = 0.0985g or more is applied perpendicular to the cantilever at the tip of the needle, the arm will not start rotating.

Below that force, the cone and the sphere are considered to be completely fixed together. Therefore, the shell of the arm does not shake at all.

In reality, the static friction force of the steel ball on the other side is 0.0158g, and the arm will not move unless a total force of 0.1143g or more is applied. The same calculation can be done for vertical movement, and the value is 0.132g.

The braking force of the AR-1 series due to static upward friction is fundamentally different from that of oil dampers and electromagnetic braking, where the braking force is only generated by the arm moving, that is, by the arm swinging, and the arm does not swing at all when the external force acting on the stylus tip is below a certain value.

Unlike other general arms, the AR-1 series does not vibrate wildly, so you can enjoy a very stable and reassuring playback with no shaking of the sound image.

About 3: How was the horizontal and vertical rotation mechanism with absolutely no wobbling realized? For two objects to rotate lightly while touching each other, a gap is necessary. This is because the precision of machining cannot be infinitely reduced. Even ultra-precise ball bearings have a 0.005mm (5μ) looseness, or gap. Normally, two ball bearings are used on each of the horizontal and vertical rotation axes of a tone arm. These two ball bearings should be spaced as far apart as possible, but tone arms are rarely spaced more than 50mm apart. Since there is a 0.005mm gap for one bearing, there may be a 0.01mm gap for two bearings. In other words, there is a 0.01mm wobble at 50mm. However, the distance between the rotation axis and the tip of the pickup needle is usually about 250mm, so the wobble is magnified five times at the needle tip, resulting in a 0.05mm wobble. This corresponds to the maximum amplitude of 50μm recorded on a record. From this, I think you understand that a general ball bearing should not be used for a tone arm.

So, what about a single-point support? As shown in the diagram, the center of rotation changes with the rotation, and the most crucial defect is that the axis of the vertical movement is not fixed at all. Stereo vibration is a vibration in a plane perpendicular to the sound groove, but rotational movement in that plane is completely unnecessary and harmful, and the vertical rotation axis of the tone arm must be fixed exactly perpendicular to the direction of the sound groove, that is, the horizontal projection direction of the cartridge cantilever. If the axis is rotated even slightly away from this perpendicular angle, the cartridge will inevitably rotate. From this, I think you understand that a general single-point support mechanism should not be used for a tone arm.

Knife edges do not have the defect of the direction of the vertical rotation axis being indefinite, but the problem of the center of rotation moving slightly when moving up and down remains. And for horizontal rotation, it is unavoidable to use ball bearings.

So, I was completely at a loss as to what to do, and because of this difficult problem, I was unable to manufacture a tone arm from Satin.

This seemingly unsolvable problem is actually very simple once you solve it, so if you look at the explanatory diagram, I think you will immediately understand.

A ball sandwiched between two conical surfaces makes circular contact with each conical surface. Therefore, the center of rotation does not move at all.

There is another ball on the side, which rolls on the disk.

The line connecting the centers of these two balls is fixed as the axis of up and down rotation, so it is necessary to make this exactly perpendicular to the axis of the cartridge.

The contact is only due to the weight of the tone arm, so there is absolutely no gap between them.

It is supported by only three points, the two balls and the cartridge stylus, so in principle there is no wobble at all. In addition, the vertical and horizontal axis rotation mechanism developed by Satin simultaneously provides the necessary damping action for a tone arm and the ability to completely cancel the inside force that changes from moment to moment due to modulation of the sound groove.

Regarding 4, in order to reduce the Q of a metal material to a non-vibrational level, a damping material of at least the same weight as the metal material is required. Since the specific gravity of the damping material is usually close to 1, a damping material of at least several times the volume of the metal material is required. There are some methods that harden the front and back of the pipe with anodized aluminum of only a few tens of microns in thickness, while the inside remains the original metal, or that increase loss by creating countless cracks on the surface of the pipe, or that attach a rubber-like damping material 1 to 2 mm thick to only one side of the metal surface, but all of these only have a moderate effect. Even if the layer of damping material is somewhat thin, it is necessary to make a true sandwich structure in which it is tightly sandwiched between structural materials that maintain rigidity.

The headshell of the Satin AR-1 series has a complete sandwich structure in this sense, and the arm pipe of the AR-1M and AR-1S also has a complete sandwich structure.

Furthermore, the same one as the IC-16 (see separate catalog) is built into all of the AR-1 series.

The Other Same Items

Newest Items In Same Category